Turf that fades within 12 months due to lack of UV protection.

Waterlogging issues because of poor drainage designs.

Fibers that split or flatten quickly, losing the natural look.

Backing that cracks or peels in hot climates, making the turf unusable.

For importers, one bad shipment doesn’t just mean a financial hit it can destroy their brand credibility, cause loss of repeat customers, and even lead to legal disputes if warranties and safety standards aren’t met.

This is why quality checks are not a formality they are the foundation of successful turf trade. Artificial turf is a technical product, and every small detail—from pile height and stitch density, to yarn material, to fire resistance certifications—can determine whether the end result is a high-performing surface or a costly failure.

At Decospaa International, we’ve worked with importers and project contractors across the Middle East, Europe, Africa, and the Americas, and we’ve seen both sides of the story. Buyers who prioritize quality, specifications, and supplier credibility consistently enjoy long-term success. On the other hand, those who cut corners on quality often find themselves paying double in replacements and customer dissatisfaction.

This guide prepared by Decospaa International, a global exporter of artificial turf is designed as your complete roadmap. Whether you’re sourcing turf for a stadium in Riyadh, a luxury resort in Spain, or a landscaping distributor in the USA, the principles remain the same. By the end of this blog, you’ll know exactly what to check before confirming a turf order from pile height and yarn type, to UV and fire resistance, to supplier credibility.

Because in global trade, especially in technical products like turf, success comes down to one thing: the quality you import is the reputation you export.

Global Artificial Turf Market Overview

The Rising Demand Worldwide

Artificial turf has moved far beyond its early image of being a niche product for football stadiums. Today, it is one of the fastest-growing sectors in the building and landscaping materials industry. Its versatility, low maintenance, and sustainability

benefits have made it a go-to solution across multiple sectors worldwide.

Sports Infrastructure

Sports Infrastructure

The backbone of turf demand still comes from sports.

Football: FIFA’s ongoing push for standardized playing surfaces has led to artificial turf being used in both international stadiums and local academies.

Cricket: Countries like the UAE and India are adopting turf for practice nets and indoor facilities, ensuring year-round play.

Rugby & Hockey: These sports often prefer synthetic surfaces for consistent ball roll and reduced injuries.

Tennis & Golf: Turf is increasingly being used for multi-sport courts and putting greens, especially in resorts and residential projects.

Multi-sport Academies: Schools and universities worldwide are shifting to turf as it reduces maintenance cost compared to natural fields.

Landscaping Applications

Landscaping Applications

Beyond sports, the biggest growth driver is residential and commercial landscaping.

Villas and luxury residences in Europe and the Middle East use turf for lawns, balconies, and gardens.

Rooftops in cities like Dubai, London, and New York are being transformed into green leisure zones.

Around swimming pool decks, artificial turf is used for its softness, drainage, and slip resistance.

Builders and developers prefer turf as it adds visual appeal and resale value without the hassle of daily watering or mowing.

Villas and luxury residences in Europe and the Middle East use turf for lawns, balconies, and gardens.

Rooftops in cities like Dubai, London, and New York are being transformed into green leisure zones.

Around swimming pool decks, artificial turf is used for its softness, drainage, and slip resistance.

Builders and developers prefer turf as it adds visual appeal and resale value without the hassle of daily watering or mowing.

Commercial Spaces

Commercial Spaces

Businesses have embraced artificial turf as part of modern design aesthetics.

Schools and playgrounds use it for safe, durable, and low-maintenance flooring.

Resorts, hotels, and gyms incorporate turf into outdoor relaxation zones, mini-golf, and training areas.

Offices and co-working spaces now use turf for creative indoor spaces that bring nature indoors.

Schools and playgrounds use it for safe, durable, and low-maintenance flooring.

Resorts, hotels, and gyms incorporate turf into outdoor relaxation zones, mini-golf, and training areas.

Offices and co-working spaces now use turf for creative indoor spaces that bring nature indoors.

Specialty Applications

Specialty Applications

Artificial turf’s flexibility has also created unique, niche applications:

Pet Turf: Special turf designed with drainage layers for dogs and cats.

Event Décor: Used in exhibitions, trade shows, and weddings to create green-themed installations.

Temporary Installations: Quick-lay turf systems for expos, concerts, or short-term events.

The takeaway: artificial turf has become mainstream across industries. Its adaptability and durability make it one of the most profitable and scalable export categories.

TOP IMPORTING REGIONS

Excellent Medical Services

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

World Best Doctors

" When my mother was diagnosed with cancer, we knew that Hospy is the hospital we could trust. Their state of the art facilities made my mother feel at ease. After 6 months of treatment, my mother was completely healed. I owe it all to the professionals here at Hospy. Thank you so much! "

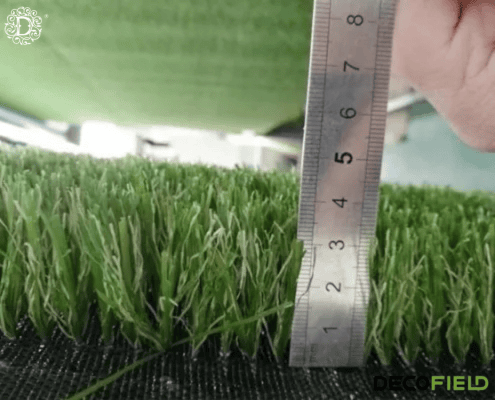

Pile Height Explained

Pile height is the length of the turf fibers, usually measured in millimeters. It determines not just the look and feel of the turf but also its functionality

landscaping

This range is ideal for residential lawns, gardens, balconies, and decorative landscaping projects.

Shorter pile heights (~25 mm) create a tidy, freshly-cut look, while longer ones (~35–40 mm) give a lush, natural appearance.

Easy to maintain: shorter fibers are less likely to flatten and easier to brush up.Best suited for buyersBest suited for buyers

targeting the luxury home market, villa landscaping, and commercial décor.

Sports Turf

Sports Turf

Sports fields, especially football, rugby, and cricket, require longer pile heights in the 40–60 mm range.

This ensures a realistic ball bounce and roll, player comfort, and shock absorption.

Heavier infill (sand + rubber granules) is usually added for stability.

For FIFA-standard football fields, 50–60 mm pile height is the global benchmark.

Playgrounds & Multi-Use Turf

Shorter pile turf is often used in school playgrounds, gyms, or multi-sport courts.

Easy cleaning.

Minimal infill needed.

High durability against constant foot traffic.

The wrong pile height leads to performance failures. Imagine ordering 25 mm turf for a football field—the ball won’t bounce naturally, and complaints will follow. Similarly, 60 mm turf in a balcony makes it look unnatural and hard to clean. Matching pile height to the end-use is non-negotiable.

High-Density Turf

Medium-Density Turf

Good for mid-range residential landscaping and school playgrounds.

Well-Suited for School Playgrounds

Low-Density Turf

Might seem cheap upfront but often requires replacement in 1–2 years.

Only suitable for temporary events or budget.

Importer Tip: How to Verify Pile Height & Density

- Request a Spec Sheet: A professional exporter should provide pile height, stitch rate, yarn type, and backing details upfront.

- Sample Swatches: Always compare at least 2–3 turf samples physically.

- Feel Test: Run your hand over the turf—low-density feels sparse, while high-density feels full and lush.

- Weigh It: Higher-density turf rolls weigh significantly more. A 25 mm, 10,500 stitch turf will weigh far less than a 35 mm, 16,800 stitch turf of the same size.

Decospaa’s Standard for Pile Height & Density

Decospaa’s Standard for Pile Height & Density

- At Decospaa International, we follow strict guidelines for matching turf specs to application:

- Residential & Commercial Landscaping → 25–40 mm pile, 14,700–16,800 stitches/m².

- Sports Fields (Football, Cricket, Rugby) → 40–60 mm pile, 16,800+ stitches/m².

- Playgrounds & Gyms → 15–25 mm pile, high stitch density for durability.

- Special Projects (Pets, Events, Rooftops) → Customized pile heights, density adjusted for quick install/remove.

Polyethylene (PE): The Global Standard

What Importers Usually Get Wrong

Choosing PP for Sports

Overpaying for Nylon

Not Asking for Yarn

Importer Tip: How to Match Yarn to End-Use

Sports (football, rugby, cricket, hockey) → Always use PE.

Playgrounds & Schools → PE short pile for durability + safety.

Landscaping (gardens, villas, rooftops, balconies) → PE for premium; PP for budget.

Decospaa’s Yarn Standards

Made from 100% polyethylene (PE) yarn, providing excellent durability, resilience, and softness—ideal for high-impact activities.

UV-stabilized and fire-retardant for enhanced safety and longevity.

Landscaping Turf: PE for premium, PP only for budget clients (clearly labeled).

Golf/High-End Projects: Nylon available on request.

All yarn sourced from internationally certified manufacturers with strict QC.

Final Word: Yarn Defines Performance

Polyethylene is the industry-standard yarn for most artificial turf applications due to its superior durability, softness, and UV resistance.

Ideal for sports fields, residential landscaping, commercial spaces, and school grounds, PE delivers a natural look with excellent wear resistance.

Widely accepted by international markets and regulatory bodies, making it the go-to choice for projects requiring proven performance and compliance.

Offers a strong balance between cost, aesthetics, and lifespan, making it the most versatile option across all mid-to-premium segments.

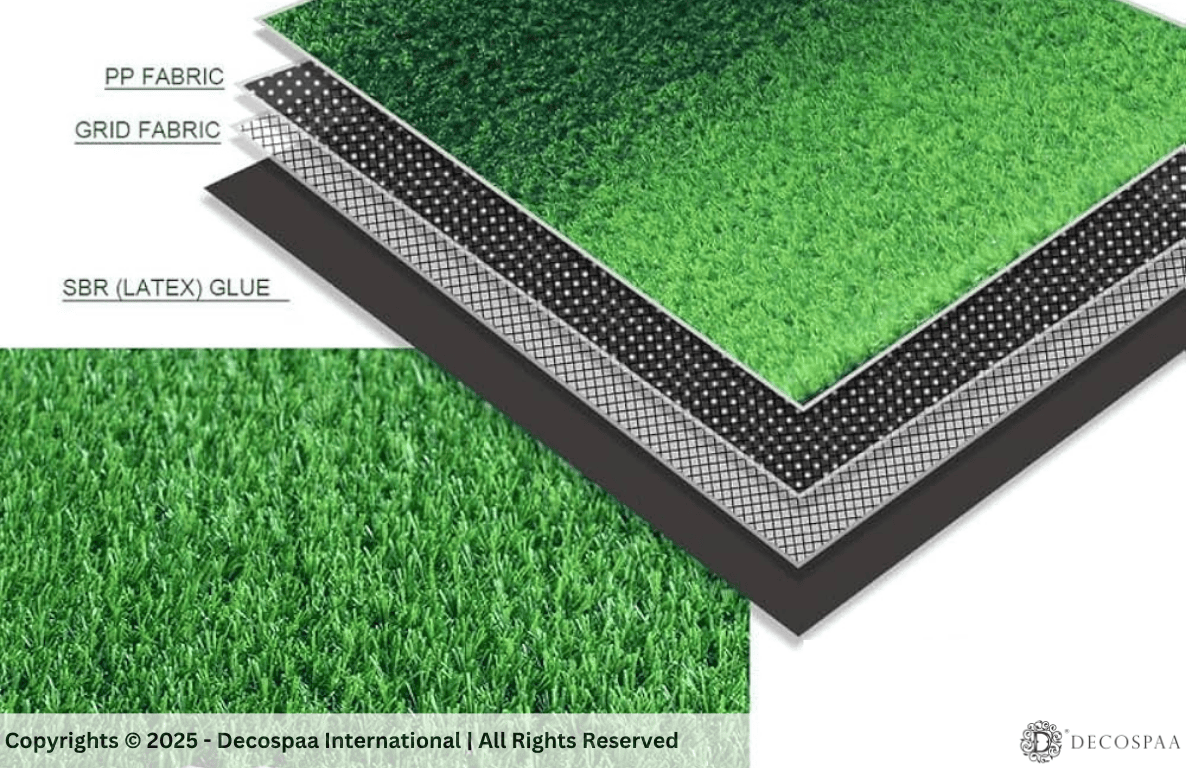

Types of Turf Backing

Primary Backing

Usually made of woven polypropylene (PP) fabric.

Acts as the base cloth into which the fibers are tufted.

The quality of the weave determines how well the fibers are held before coating.

Secondary Backing

Applied after tufting to lock the fibers in place.

Provides strength, dimensional stability, and durability.

Coatings include Polyurethane (PU) or SBR Latex.

Why Backing Strength Matters

Fiber Retention

Dimensional Stability

Weather Resistance

Latex Coating – The Economical Option

Economical → Cheaper than PU, suitable for budget projects.

Good Fiber Locking → Adequate for moderate climates.

Widely Available → Most suppliers in China and Vietnam offer latex-coated turf.

Heat Sensitivity → Latex tends to harden and crack under high temperatures.

Water Absorption → May retain moisture, leading to odor or mold in humid climates.

Heavier Rolls → Adds to shipping costs compared to PU.

Residential landscaping in Europe and Asia (moderate weather).

Short-term installations (events, exhibitions).

Budget-conscious projects.

Final Word: Backing Defines Turf Longevity

For buyers, the choice between PU and Latex is not just about price—it’s about long-term client satisfaction. A slightly higher upfront cost for PU can save tens of thousands in replacements and complaints.

Pro Tip for Importers: Always specify PU coating for hot, humid, or premium projects. Use Latex only for budget projects in mild climates.

At Decospaa International, we make this choice simple by advising importers honestly, supplying both options, and ensuring backing strength matches project needs. Because in turf exports, the hidden layers decide the visible success.

Artificial turf is more than just aesthetics—it is often installed in public spaces like schools, stadiums, playgrounds, and commercial complexes. In such environments, fire safety and toxicity compliance are non-negotiable. A turf that fails under fire tests or contains harmful chemicals can lead to serious legal liabilities, warranty claims, and reputational damage for importers.

For this reason, every importer must ensure the turf they buy meets international fire resistance and safety standards

Turf can ignite quickly, causing accidents.

Fire can spread faster, especially in stadiums or schools.

Fibers can melt and drip, leading to severe injuries.

EN 13501-1 is the European standard for classifying building materials.

Turf is graded from A (non-combustible) to F (easily flammable).

For schools, stadiums, and playgrounds, most EU countries demand.

ASTM D2859 (Methenamine Pill Test) → Determines turf’s ignition resistance.

ASTM E648 (Radiant Panel Test) → Measures flame spread on flooring.

ASTM E662 → Tests smoke density.

REACH (Europe) → Ensures turf is free from harmful substances like lead, cadmium.

RoHS (Restriction of Hazardous Substances) → Limits heavy metals and dangerous.

EN 71-3 (Toy Safety Standard) → Often applied in playgrounds to confirm turf.

Landscape Turf

Used in gardens, villas, rooftops, balconies, and commercial landscaping.

UV stability (no fading beyond an acceptable range).

Fiber integrity (no premature splitting or shedding).

Backing performance (no cracking, peeling, or shrinkage).

Types of Certifications Importers Must Check

FIFA Quality & FIFA Quality Pro

Gold standard for football turf worldwide.

Turf undergoes tests for ball roll, shock absorption, UV resistance, durability, and player safety.

FIFA Quality Pro is the highest grade, used in professional stadiums.

RoHS Compliance

Restriction of Hazardous Substances.

Ensures turf backing, yarn, and pigments don’t contain restricted elements.

ISO Certifications

ISO 9001: Quality management certification. Ensures the factory has standardized production processes and QC systems.

ISO 14001: Environmental management certification. Confirms production is eco-friendly and sustainable.

EN 71-3 (Toy Safety Standard)

Ensures materials are safe for children.

Mandatory for turf installed in playgrounds, schools, and nurseries.

REACH Compliance (Europe)

Mandatory in the European Union.

Ensures turf is free from toxic chemicals, heavy metals, or harmful substances like lead and cadmium.

Critical for projects in schools, playgrounds, and residential areas.

Other Sports Certifications

FIH Certification → For hockey fields.

World Rugby Certification → For rugby pitches.

Accepting Verbal Warranties

Many suppliers promise “5 years warranty” but provide no written documentation.

Without written proof, warranty claims cannot be enforced.

Overlooking Certification Expiry

Check validity dates regularly to ensure certifications are up to date.

Set up reminders or automated alerts for upcoming expiry dates to avoid missing renewal deadlines.

Assuming All Turf Is Certified

Not Matching Certification to Application

Request Certificates in Writing

Ask for official PDF copies from accredited labs or agencies.

Cross-check with certification databases (FIFA, ISO).

Demand Warranty Letters

Warranties should be on supplier letterhead with coverage details.

Must include duration, terms, exclusions, and validity.

Check Lab Accreditation

Ensure the lab's scope of accreditation covers the specific tests being performed.

Check the validity of the lab’s accreditation certificate, including expiration dates and issuing body.

Verify Scope of Coverage

Does the warranty cover UV fading, fiber integrity, and backing performance?

Or is it limited only to “manufacturing defects”?